We bring pressure-pipe condition assessment ‘down-to-the-stick’

From boreholes and chimneys to water mains, boilers and storage tanks, non-destructive acoustic testing helps monitor vital infrastructure across the globe.

Pipe Integrity Inspection (PII) represents the most advanced implementation of these principles for small-diameter pressure pipes. The culmination of over a decade of validated research and development, PII offers improved accuracy, resolution, economics, and ease of use.

Using a controlled sound source and externally mounted sensors, PII determines the complex-valued wavenumbers as well as the dynamic coupling of the liquid column to the pipe wall and the pipe wall to the backfill from which specific properties, such as the pipe wall’s thickness and stiffness, are characterized to ascertain if the pipe is fit for purpose, helping avoid failures and unnecessary replacement of good pipe.�

PipeSonic’s technology can resolve these pipe characteristics down to an individual stick of pipe with leaks and obstructions located within several feet. By comparing measured propagation speeds and the dynamic modulus of the pipe with PII’s database of validated values, the material of the pipe can also be identified.

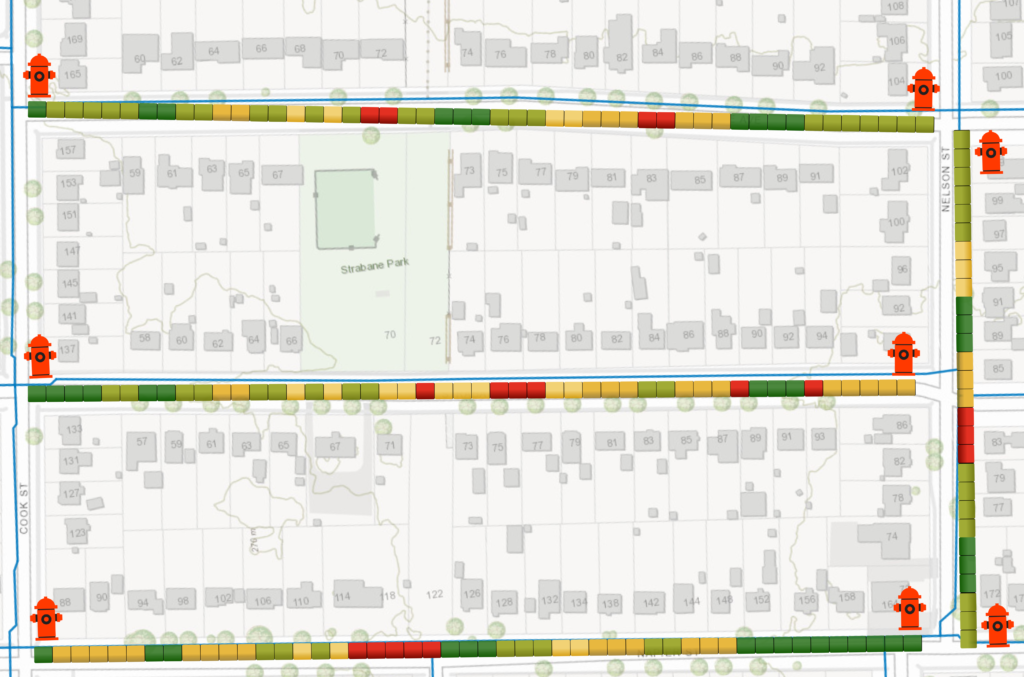

PII provides a heatmap that identifies and differentiates between:

Thanks to PII’s high resolution, repair teams can precisely address problem areas, reducing costs and minimizing disruptions to the public. This level of detail allows managers to allocate budgets with clinical precision, delivering an increase in savings.